Industries often deal with a variety of pollutants that may require different purification methods, making it difficult to design a one-size-fits-all solution.

Ensuring that new purification technologies seamlessly integrate with existing processes and infrastructure can be a significant challenge.

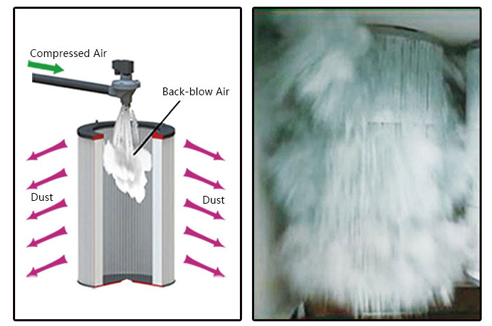

Automatic ash cleaning

Large Air Volume

Easy To Maintain