Committed to providing every Moland user with a safe, clean and healthy working environment.

Founded in 2016, Moland is a global leader in purification solutions, serving the automotive, railway, engineering machinery, marine engineering, aviation and other industries.

The company is committed to reducing the impact of the pro-duction process on the environment, protecting workers from harmful gases and smoke and dust, and creating a cleaner working environment.

Years of exp

R&D Engineers & Technicians

Countries & Regions

Manufacturing Base

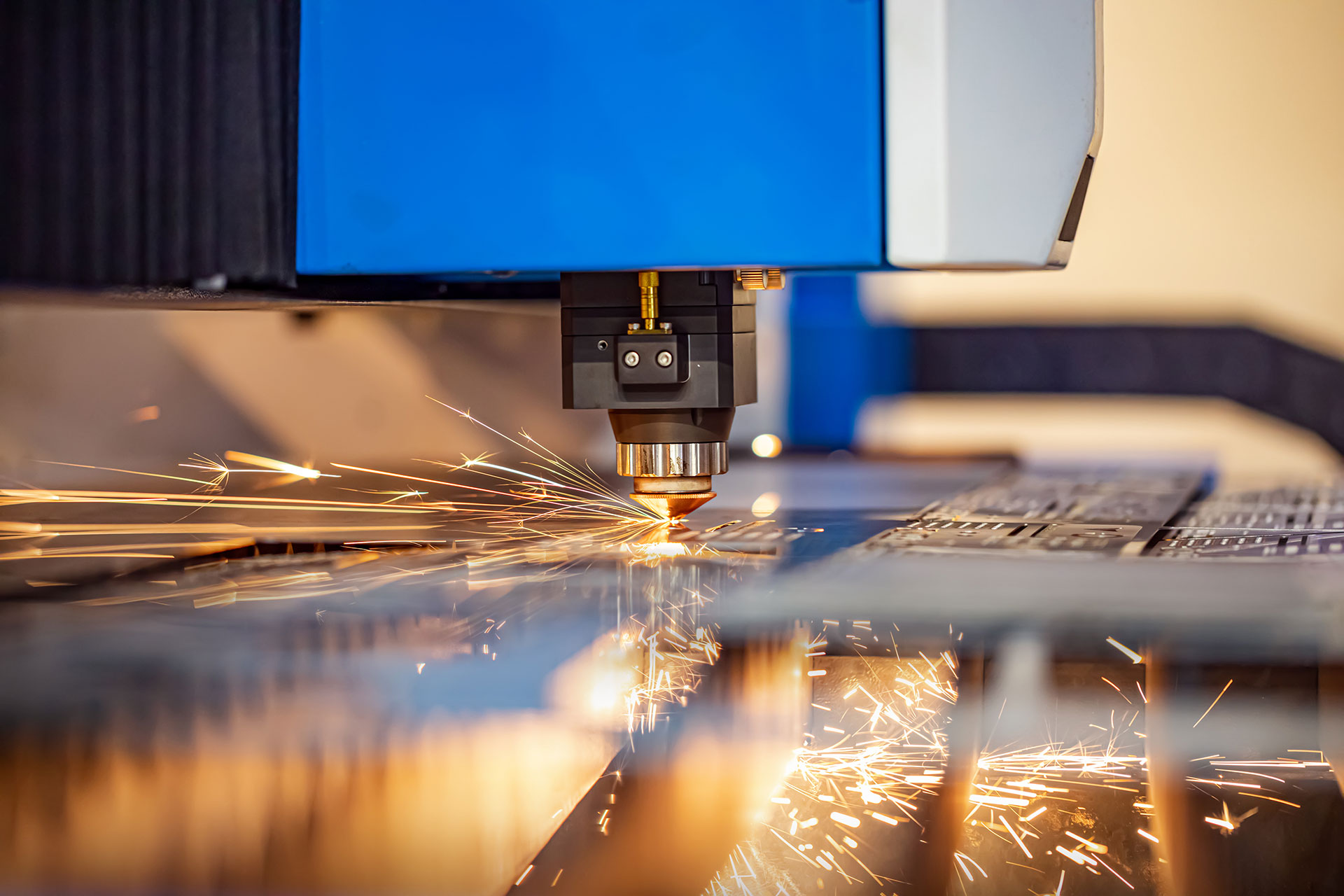

Thermal cutting applications, such as laser cutting, generate considerable levels of fume and particulate that may present a health risk to operators and be detrimental to cutting machine.

Discover More

The MLWF series cartridge filter dust collectors are equipped with a reverse jet pulse filter cleaning system and high-efficiency filters, which can provide optimal performance and filter life, allowing your workers to have a healthy working environment. Intelligent control system can display the equipment operating status in real time, maintenance warning, and fault alarm, to protect your safe production.

Discover More

The MLWF series cartridge filter dust collectors are equipped with a reverse jet pulse filter cleaning system and high-efficiency filters, which can provide optimal performance and filter life, allowing your workers to have a healthy working environment. Intelligent control system can display the equipment operating status in real time, maintenance warning, and fault alarm, to protect your safe production.

Discover More

The MLWF series cartridge filter dust collectors are equipped with a reverse jet pulse filter cleaning system and high-efficiency filters, which can provide optimal performance and filter life, allowing your workers to have a healthy working environment. Intelligent control system can display the equipment operating status in real time, maintenance warning, and fault alarm, to protect your safe production.

Discover More

The MLWF series cartridge filter dust collectors are equipped with a reverse jet pulse filter cleaning system and high-efficiency filters, which can provide optimal performance and filter life, allowing your workers to have a healthy working environment. Intelligent control system can display the equipment operating status in real time, maintenance warning, and fault alarm, to protect your safe production and modular structure can be freely combined according to working conditions to ensure the scalability of power and filtration area.

Discover More

This product is designed to capture and clean smoke and dust from light-duty welding, soldering, and grinding applications. When operating, air is drawn in to the nozzle, passes through the 40mm diameter hose, then through the air cleaner’s filtration system, and is finally exhausted through the side discharge.

Discover More

The Mobile Fume Extractor features two directional and two rotary polyurethane casters with brakes for easy mobility and stability. It's designed for fume and dust purification from welding, grinding, and various processes, as well as for collecting rare metal particles and valuable materials.

Discover More

The Mobile Fume Extractor features two directional and two rotary polyurethane casters with brakes for easy mobility and stability. It's designed for fume and dust purification from welding, grinding, and various processes, as well as for collecting rare metal particles and valuable materials.

Discover More

Industrial grinding processes generate significant amounts of dust and particulate matter, posing risks to both worker health and equipment performance. Effective dust purification systems are essential for maintaining a safe and efficient working environment.

Learn More

Laser cutting processes generate significant smoke and particulate matter, which can impact air quality and worker safety. Effective dust purification systems are crucial for capturing these emissions and maintaining a clean, safe working environment.

Learn More

Industrial processes often release harmful waste gases that pose serious environmental and health risks. Effective waste gas purification systems are essential for capturing and treating these emissions, ensuring compliance with regulatory standards.

Learn More

Customized purification solutions are tailored to meet the specific needs of various industries, addressing unique challenges related to air, gas, and liquid contaminants.

Learn More